High-quality Products

Manufacturing, done better.

Kabert Industries provides the necessary resources for companies to make their products the best they can be.

-

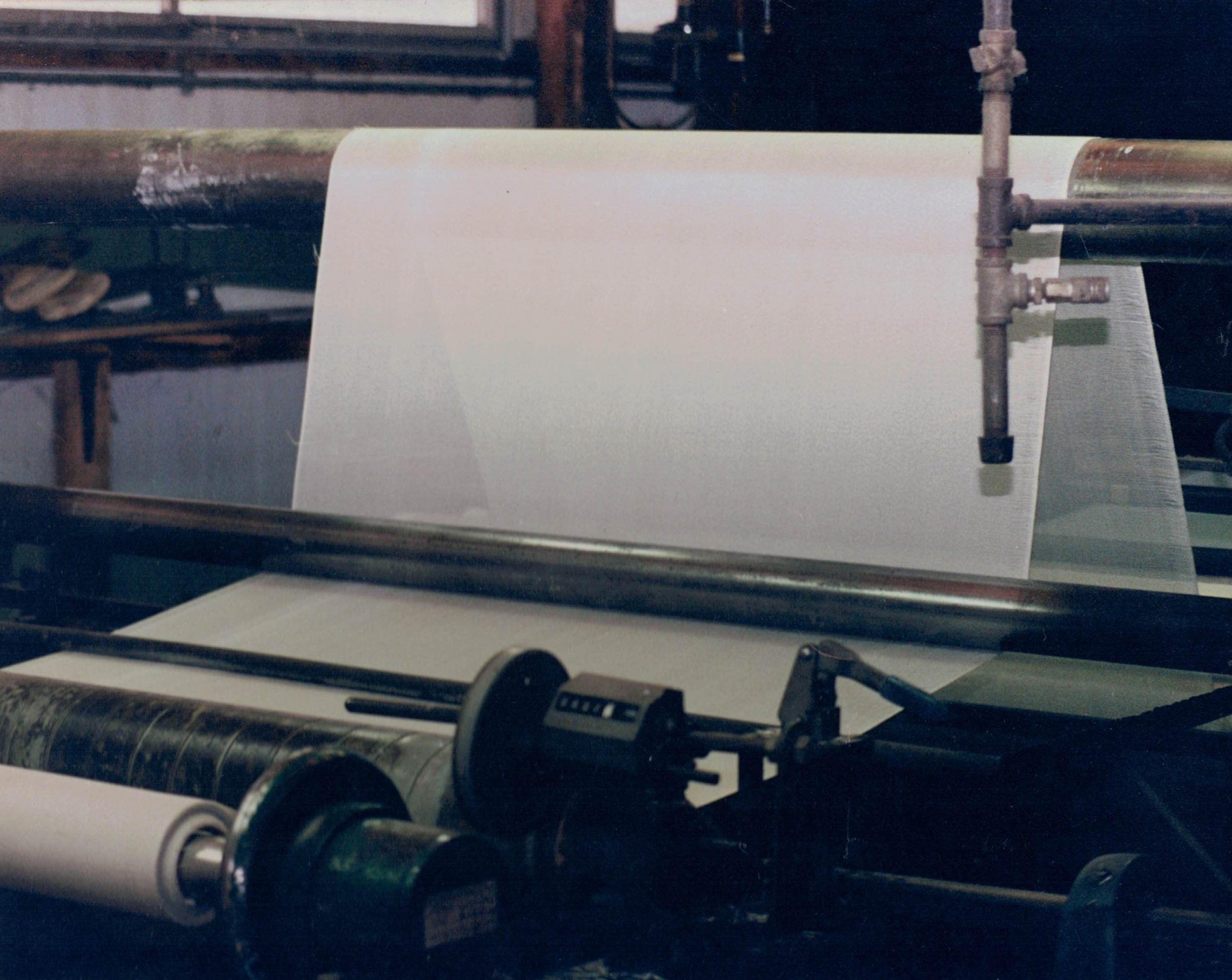

Since 1979 Kabert Industries has been weaving fiberglass cloth in Lynn, Indiana for the aluminum industry. Fiberglass cloth is an inexpensive and effective method of non-ferrous molten metal distribution and filtration.

Kabert Industries cloth is available in a variety of styles. Plain weave is a simple weave where the warp yarns run over and under the fill yarns. Similarly, twill weave consists of the warp yarns running over two or more fill yarns. The leno weave style interlocks the warp yarns, which cross over each other and join together with the fill yarns. Also, three, four and six strand cloths are available.

All of Kabert Industries cloth is woven to specification on approximately 100 linear yard rolls. Standard widths are obtainable for each style. Minimum orders may apply on some widths. Standard or brown finishes are available.

-

Gaskets are an inexpensive method of sealing and insulating troughs.

Fiberglass insulation is die or hand cut to any specification gasket.

Gaskets can be sewn onto fiberglass trough socks to filter out large impurities upstream so they will not break the sniff nozzle and downstream so they will not block the control pin.

The temperature prior to breakdown is 600 to 700 degrees F.

Fiberglass insulation is available in a variety of thickness and densities.

Density: 2 LB, 3 LB, 4 LB, 6 LB

Thickness: 1/2", 3/4", 1"

-

Kabert Industries vacuum formed shapes are produced by dewatering a slurry of Fiberfrax Bulk Ceramic Fibers and special high temperature binders. This manufacturing method permits considerable freedom to vary shape, thickness, density and hardness. Often the vacuum casting technique provides the most economical answer to producing large quantities of parts in simple or complex configurations.

ADVANTAGES OF VACUUM FORMED SHAPES

High temperature stability

Low thermal conductivity

Low heat storage

Lightweight

Thermal shock resistant

High heat reflectance

Excellent corrosion resistance

CHEMICAL PROPERTIES

Our vacuum formed shapes resist attack from the most corrosive agents. Exceptions are hydrofluoric and phosphoric acids and concentrated alkalies. Vacuum cast parts also resist oxidation and reduction. If wet by water or steam, thermal and physical properties are completely restored upon drying. No water of hydration is present.

TYPICAL PHYSICAL PROPERTIES

Color Off-White

Basic Composition Alumina-Silica

Continuous Use Limit* 1260 degrees C (2300 degrees F)

Melting Point 1790 degrees C (3260 degrees F)

Density Range 190-640 kg/m3 (12-40 lb/ft3)

Thickness Range 3.2 mm (1/8") up

Specific Heat 1093 C (2000 F) 1130j/kg3 C (.27btu/lb F)

*The continuous use limit of Kabert products is determined by irreversible linear change criteria, not by product melting point.

TYPICAL CHEMICAL ANALYSIS

A1203 49.2%

Ti02 0.02%

Si02 50.5%

K20 0.03%

FE203 0.06%

NA20 0.20%

Leachable Chlorides

-

An inexpensive and effective method of distributing molten aluminum to appropriate areas of the mold. Kabert Industries mini channel bags have been successfully used since 1980 in all alloys including body and lid.

REDUCES CRACKED INGOTS

The closeweave outer jacket distributes hot metal away from the center to the ends of the mold reducing the possibility of a dished butt crack at the start of a cast.

REDUCES HOT TEARS

The closeweave outer jacket directs hot metal away from the center to the ends of the mold during casting.

REDUCES INCLUSIONS

The open weave lessens the possibility of build-up inside the bag during casting.

ELIMINATES TAP BAG PROBLEMS

The open weave allows less build-up during casting.

ELIMINATES BAG FREEZING TO BLOCK

The mini channel bag and combo bag do not sit as close to the bottom block.

ELIMINATES DIRT IN HEAD OF INGOT AT END OF CAST

BETTER INGOT SURFACE

Reduces hot metal to ingot face.

EASY CAST START

Not as many bags in the head to be concerned about. Bag rapping is not necessary. Reduces excess smoke.

LIKED BY FURNACE CREWS

Easier to install and remove.

VARIETY OF DESIGNS AND HANGING METHODS

Standard designs in stock. Any size or style manufactured to specification. Special hangers can be installed in trough.

SELECTION OF FIBERGLASS CLOTH

Plain, twill or leno weave cloths are available. Three, four or six strand fiberglass cloth ready for use. Standard or brown finishes available.

Fiberglass Cloth Details

Style Number

KI-2433

KI-2403

KI-2383

KI-2373

KI-2363

KI-2353

KI-2384

KI-2374

KI-2366

KI-1590

KI-1553

KI-1593

KI-1613

KI-1653

KI-7628

KI-3434

KI-3712220

Strand Warp

0.03

0.03

0.03

0.033

0.033

0.033

0.032

0.033

0.045

0.04

0.021

0.021

0.021

0.021

Dia. Fill

0.033

0.033

0.033

0.035

0.035

0.035

0.035

0.035

0.045

0.035

0.025

0.025

0.025

0.025

Tck.

0.007

0.012

0.025

Strand Ct.

14 x 13

12 x 12

10 x 10

9 x 9

8 x 8

7 x 7

10 x 10

9 x 9

8 x 8

5 x 5

17 x 17

20 x 18

20 x 20

20 x 22

44 x 32

34 x 34

24 x 20

Holes Per Sq. Inch

182

144

100

81

64

49

100

81

64

25

289

360

400

440

Closeweave

Closeweave

Closeweave

Hole Size

0.00182

0.00273

0.00469

0.00595

0.00828

0.01185

0.00442

0.00595

0.0064

0.0264

0.00128

0.00089

0.00073

0.00061

Percent Open Area

33.1

39.1

46.9

48.2

53

58.1

44.2

48.2

41

66

37

31.9

29

26.9